NBC-315Y 220V/380V 300A IGBT Inverter Portable welder Built-in wire feeder 2T/4T MIG/MAG(GMAW)

Cat:Gas shielded welding machine

1、The machine adopts a phase-shifted full-bridge inverter main circuit...

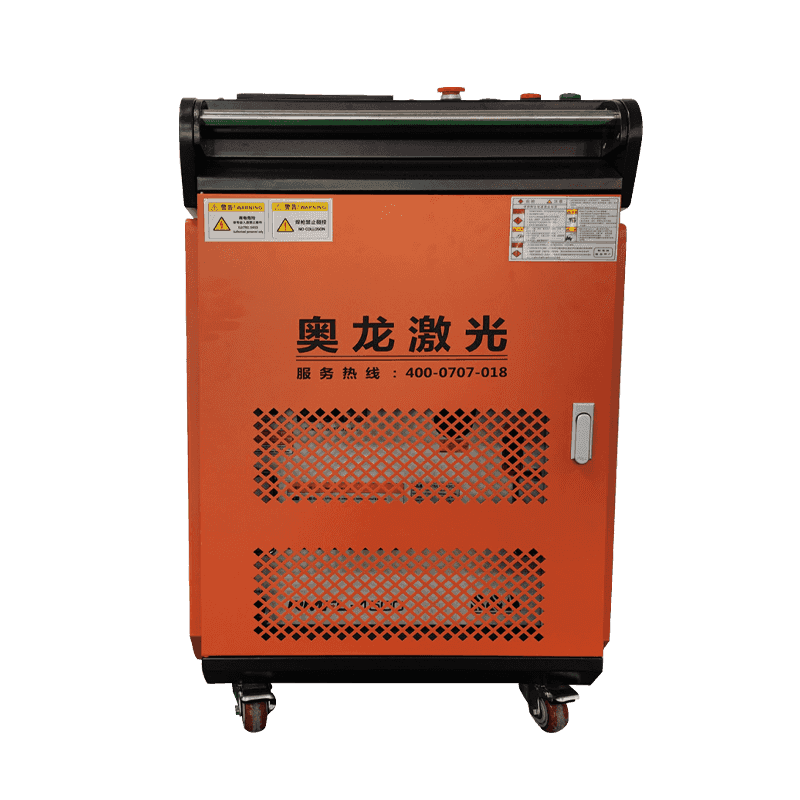

See Details3 in 1 Laser Cleaning Welding Cutting Machines combine three functions: laser cleaning, welding and cutting. Therefore, it is very important to consider multiple aspects when ensuring the safety and stability of the equipment. Here are some common safety and stability protection measures:

Laser safety protection

Laser protective cover: Ensure that the operator avoids direct contact with the laser beam during operation to prevent laser damage.

Laser sensing system: Use laser intensity sensing and control system to monitor the laser output power in real time to avoid overheating or other safety problems caused by excessive output.

Laser shielding device: When the equipment is working, a physical barrier or automatic shielding system is used to ensure that the laser only acts on the target area to prevent the spilled laser from causing danger to the surrounding environment or personnel.

Stability guarantee

Cooling system: Laser equipment needs a strong cooling system to maintain stable operation of the equipment. For equipment that integrates multiple functions, the cooling system is particularly important to avoid overheating and damage to the equipment or reduce the service life of the equipment.

Vibration and anti-interference design: There will be high-frequency vibrations during laser welding and cutting, so the equipment needs to have sufficient anti-vibration design and stability. For example, use high-quality mechanical structure to enhance the shock resistance of the equipment and ensure the long-term stability of the laser and other key components.

Motion control system: High-precision motion control systems (such as servo motors and closed-loop feedback systems) can ensure the accuracy and stability of the equipment's working position and prevent misoperation or position deviation from affecting the final effect.

Electrical and mechanical safety

Electrical protection: The equipment is equipped with multiple electrical protection devices, such as overload protection, short circuit protection, overvoltage protection, etc., to prevent electrical failures from causing equipment damage or safety accidents.

Emergency stop function: The equipment design should include an emergency stop button or automatic shutdown function to ensure that the operator can stop the equipment in time when encountering abnormal conditions to avoid the expansion of accidents.

Mechanical protection device: Safety barriers or protective doors should be set on the mechanical parts of the equipment (such as cutting and welding parts) to prevent operators from contacting moving parts.

Software and system monitoring

Real-time monitoring system: Through the built-in intelligent monitoring system, the operating status, laser power, cooling system, etc. of the equipment are checked in real time to ensure that all parameters are within the safe range. If an abnormality is found, an alarm can be automatically triggered or protective measures can be triggered.

Fault diagnosis function: High-end 3 in 1 devices usually have self-diagnosis functions, which can detect equipment failures or abnormalities in real time and remind operators through the display or system.

Operator training

Professional training: Operators need to undergo rigorous training, master laser safety operation specifications, understand the functions of the equipment and emergency handling methods. Be familiar with the operation process and maintenance methods of the equipment to ensure the long-term stable operation of the equipment.

Through these measures, the safety and stability of the 3 in 1 laser cleaning welding and cutting machine during operation can be effectively guaranteed. If there is a specific brand or model of equipment, you can also refer to its dedicated safety operation manual and technical guidance.

Contact Us