NBC-315S/NBC-350S 380V 350A IGBT Inverter Portable welder 2T/4T MIG/MAG/MMA(GMAW/SMAW)

Cat:Gas shielded welding machine

1、The welding machine is small and can be connected to a wire feeder. ...

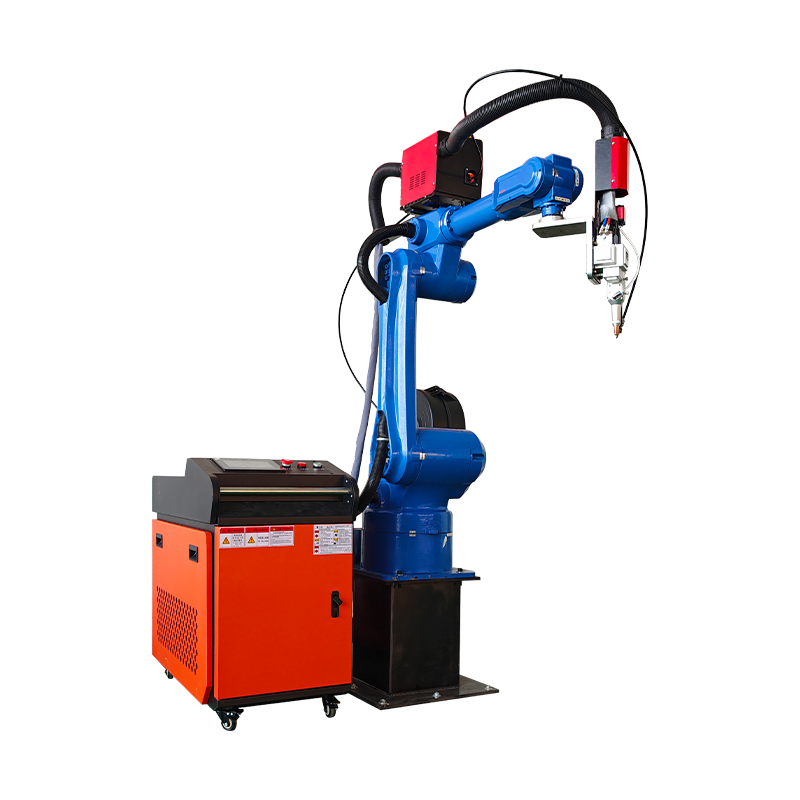

See DetailsWith the development of modern manufacturing, robotic welding, as an efficient and precise welding method, is widely used in various fields. However, welding operations in high-temperature environments will bring a series of challenges and impacts. This article will explore the problems and countermeasures faced by robotic welding in high-temperature operations.

Welding operations in high-temperature environments will have a certain impact on robotic welding equipment. High temperatures will accelerate the aging and damage of equipment and reduce its service life. In particular, electronic components and electrical components in welding equipment are easily affected by high temperatures and fail, resulting in equipment failure and downtime.

In high-temperature environments, the melting point and fluidity of welding materials will change, and the welding quality is difficult to guarantee. Welding temperatures that are too high or too low will affect the quality and strength of welded joints, and even cause welding defects. Therefore, welding operations in high-temperature environments require special attention to the control and adjustment of welding parameters to ensure welding quality.

Working in high-temperature environments poses a threat to the health and safety of operators. Long-term exposure to high temperatures can lead to health problems such as heat stroke and dehydration, and even endanger life safety. Moreover, operating welding equipment in high-temperature environments will increase the labor intensity and psychological pressure of operators, and reduce work efficiency and work quality.

The smoke and exhaust gas generated during high-temperature welding will pollute and affect the surrounding environment. The smoke and exhaust gas contain a large amount of harmful substances, such as welding smoke, carbon monoxide, nitrogen oxides, etc., which are harmful to human health and the environment. Therefore, effective measures must be taken to purify and treat welding smoke and exhaust gas to protect the cleanliness and health of the surrounding environment.

For welding operations in high-temperature environments, some of the following measures can be taken to reduce the impact and improve safety. Regularly maintain and maintain robot welding equipment to ensure its normal operation and stability. Strictly control welding parameters to ensure that welding temperature and speed are within the appropriate range to ensure welding quality. Provide operators with appropriate protective equipment, such as heat-insulating clothing, heat-insulating gloves, protective glasses, etc., to protect their health and safety. Add ventilation equipment at the welding site to strengthen air convection, remove welding smoke and exhaust gas in time, and reduce pollution. Choose environmentally friendly welding materials to reduce harmful substances generated during welding and reduce environmental pollution.

Robot welding has certain challenges in high-temperature operations, but by selecting high-temperature resistant components, lubricants, and controlling welding parameters, these challenges can be effectively addressed to ensure welding quality and safe and stable operation of equipment. At the same time, strengthening environmental monitoring and improving the heat dissipation performance of equipment are also important means to ensure the safety of high-temperature operations. With the continuous advancement of technology and continuous optimization of equipment, it is believed that the application prospects of robot welding in high-temperature operations will be broader.

Contact Us